Assembly process for cylindrical, square and prismatic batteries

General processes for every type of batteries

- Electrolyte Filling (Liquid Electrolyte)

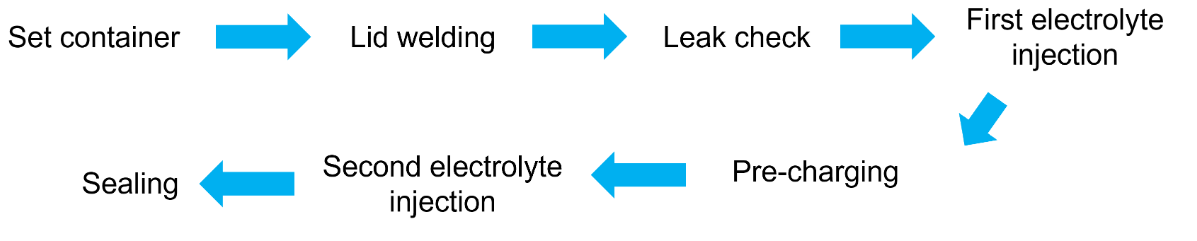

In traditional lithium-ion batteries using liquid electrolytes, the electrolyte injection process is a critical step. An opening or port is created in the battery casing to facilitate this. The liquid electrolyte, a lithium salt dissolved in a solvent, is injected into the cell through this opening. The specific electrolyte composition can vary depending on the battery design and intended application. - Venting and Degasification

- After electrolyte injection in both liquid and solid-state batteries, a degasification process is often conducted to remove any remaining gas or air from the cell. This ensures that the cell is properly filled with electrolyte. Venting may also be performed to release any excess gas produced during the formation process.

- Sealing the Battery

Once the battery is filled with the appropriate electrolyte and any excess gas has been vented, the next step is sealing the battery. The sealing process is critical for preventing electrolyte leakage and maintaining the integrity of the battery. The sealing methods may vary depending on the battery type (cylindrical, square, prismatic) and the manufacturer’s techniques. - Cylindrical Batteries

For cylindrical batteries, the open end of the cell is typically crimped or welded to seal it. This creates a hermetic seal, preventing the escape of electrolyte and ensuring the battery is airtight. - Square and Prismatic Batteries

Square and prismatic batteries are sealed using a combination of methods, including welding, adhesive bonding, and heat-sealing. These techniques are employed to achieve a secure seal that prevents electrolyte leakage and gas ingress.

Assembly process for cylindrical batteries

Assembly process for square batteries

Assembly process for prismatic batteries

Assembly process differs depending on the shape of the battery (cylindrical, square,prismatic). We can propose various machines used in the processes above according to customer requirements.

Contact

Our team can support you with price information, product information and live demonstrations.

frankfurt@djkeurope.com

Phone: +49 6196 77614-11

Fax: +49 6196 77614-19