MIXING SYSTEMS for Electrode production

Mixing process is to make slurry by active material, conductive material, binder and solvent, and ensure uniform distribution by accuarately inputting through metering, mixing and stiming by powder supply device.

The mixing process usually consists of the following process:

- Supplying powder (active material, etc) to mixer

- Pre-dispesion of binder or conductive material before main mixing for mixing effciency

- Main mixing of active material, conductive material, binder, etc.

- Storing the produced slurry and transferring it to the next process, the coating procss

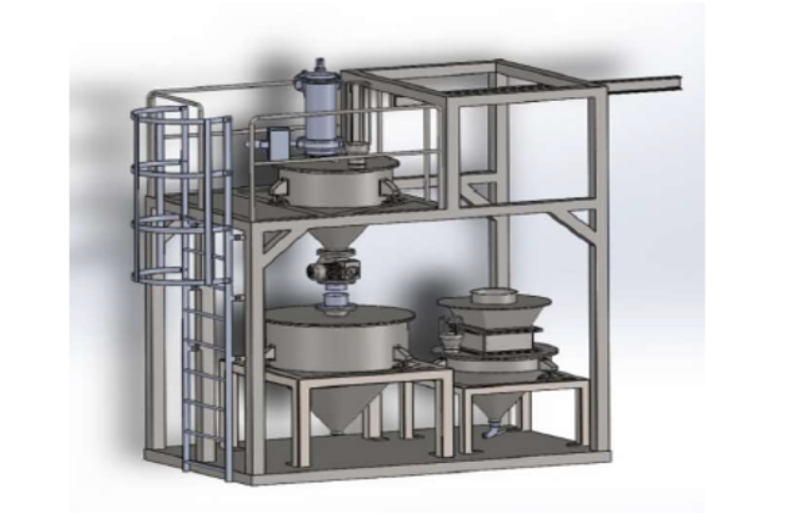

POWDER TRANSFER SYSTEMS for Electrode production

PTS (Powder Transfer System) is to transfer powder quantitively and smoothly by using air or vacuum.

PD Mixer

PD mixer has twist blades to generate big power for kneading and stirring, and have despair for high speed dispersion at the same time.

Because of efficient mixing and high volume, PD mixer is the most common mixer used in manufacturing secondary battery slurry equipment.

Contact

Our team can support you with price information, product information and live demonstrations.

frankfurt@djkeurope.com

Phone: +49 6196 77614-11

Fax: +49 6196 77614-19