Total Engineering for LIB

The demand for high-performance lithium-ion batteries continues to grow, driven by the increasing adoption of electric vehicles, portable electronics, and renewable energy storage systems.

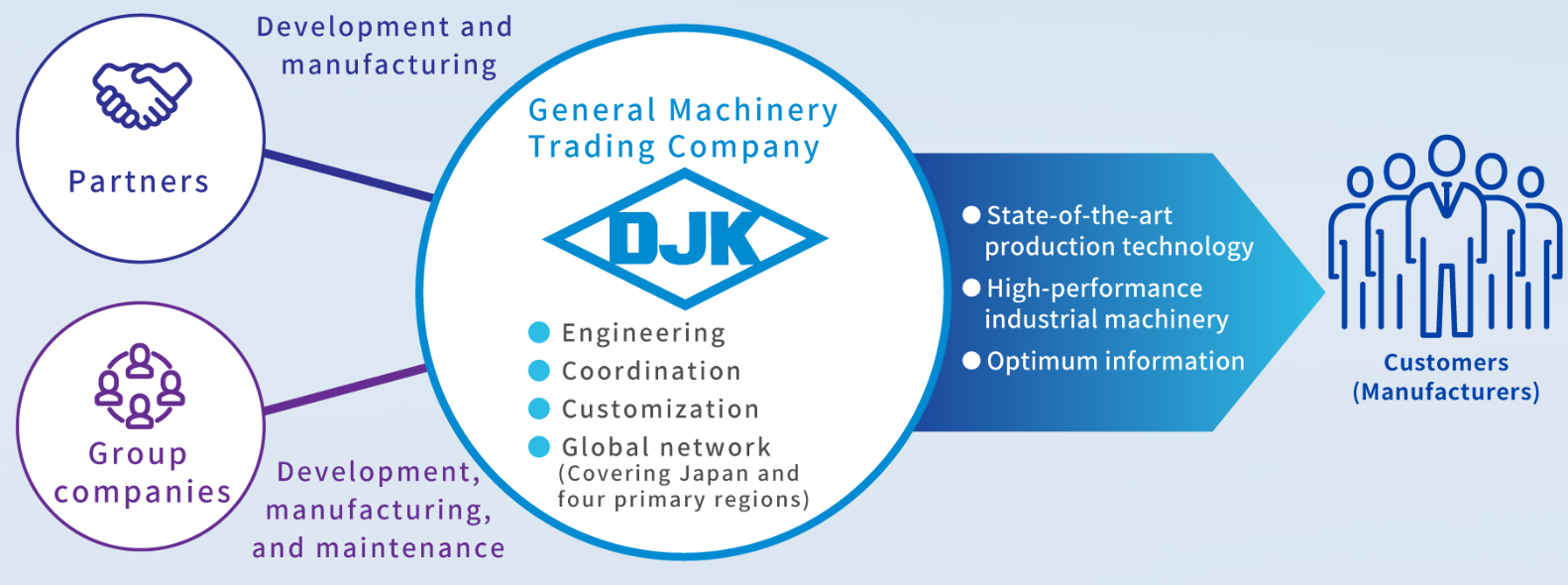

DJK specializes in providing comprehensive solutions for lithium-ion battery (LiB) manufacturing. We offer a wide range of equipment and technologies for CAM/AAM prodcution, electrode production, battery cell assembly, charging/discharging inspection and other key stages of the battery manufacturing process. With our expertise and advanced machinery, we empower manufacturers to optimize their production efficiency, enhance product quality, and stay at the forefront of the rapidly evolving battery industry.

Our commitment extends beyond machinery supply. We offer proposals for technological support, workload reduction, and issue resolution at production sites. As a one-stop solution provider, we coordinate multiple pieces of equipment, provide after-sales services, and offer support in logistics, financing, and risk management. Our collaborative approach with Group companies in Japan and overseas enables us to swiftly deliver optimum solutions and create value on a global scale.

Our Strength

The global lithium-ion battery (LiB) market is experiencing exponential growth, driven by the increasing demand for electric vehicles, portable electronics, and renewable energy storage systems. To stay ahead in this competitive landscape, manufacturers must embrace cutting-edge technologies and optimize their production processes.

At DJK ENERGY, we offer a comprehensive range of solutions that revolutionize lithium-ion battery (LiB) production. From turnkey solutions and state-of-the-art production machinery for battery material manufacturing (LCO, LFP, NCM, NCA, silicon anode, graphite anodes etc.) to advanced processes for electrode production, cell assembly, and charging/discharging inspection, we provide a holistic approach to meet the evolving needs of the industry.

Recognizing the diverse requirements of cathode and anode material production, DJK ENERGY specializes in delivering tailored machinery solutions. Whether it’s precision coating systems for LFP cathode production, cutting-edge equipment for NCM or NCA cathodes, or specialized machinery for Graphite and Silicon-based anodes, our solutions are designed to optimize efficiency, quality, and overall performance.

In electrode production, our advanced machinery and precise processes ensure the consistent quality and uniformity of electrodes. Our turnkey solutions streamline the entire production process, from material preparation and coating to calendaring and slitting, enabling manufacturers to achieve optimized productivity and exceptional electrode performance.

For battery cell assembly, our innovative technologies and automation solutions facilitate efficient electrode stacking, electrolyte filling, and cell sealing processes. This ensures the consistent production of high-quality battery cells, meeting the demands of various applications.

Furthermore, we understand the critical importance of charging/discharging inspection to guarantee battery performance and reliability. Our advanced testing and inspection solutions enable manufacturers to thoroughly evaluate the capacity, efficiency, and overall performance of the LiB cells, ensuring consistent quality control.

With our extensive experience and global presence, we have successfully delivered our solutions to clients worldwide. Our expertise ensures seamless installations, comprehensive technical support, and reliable after-sales service, regardless of geographical location.

Choose our turnkey solutions, roller hearth kilns, and advanced manufacturing processes to revolutionize your lithium-ion battery (LiB) production. Embrace the future of battery manufacturing while benefitting from our industry-leading expertise and commitment to excellence.