NARA Hybridization System (NHS)

Optimizing particle features

The NARA Hybridization System (NHS) is a technology for surface modification, preparation of composite materials of fine particles and precise mixing in a dry powder process. The raw material is dispersed in a high-speed air flow and processed by mechanical impact and shear forces. As a result, the raw material processing is not restricted by chemical laws.

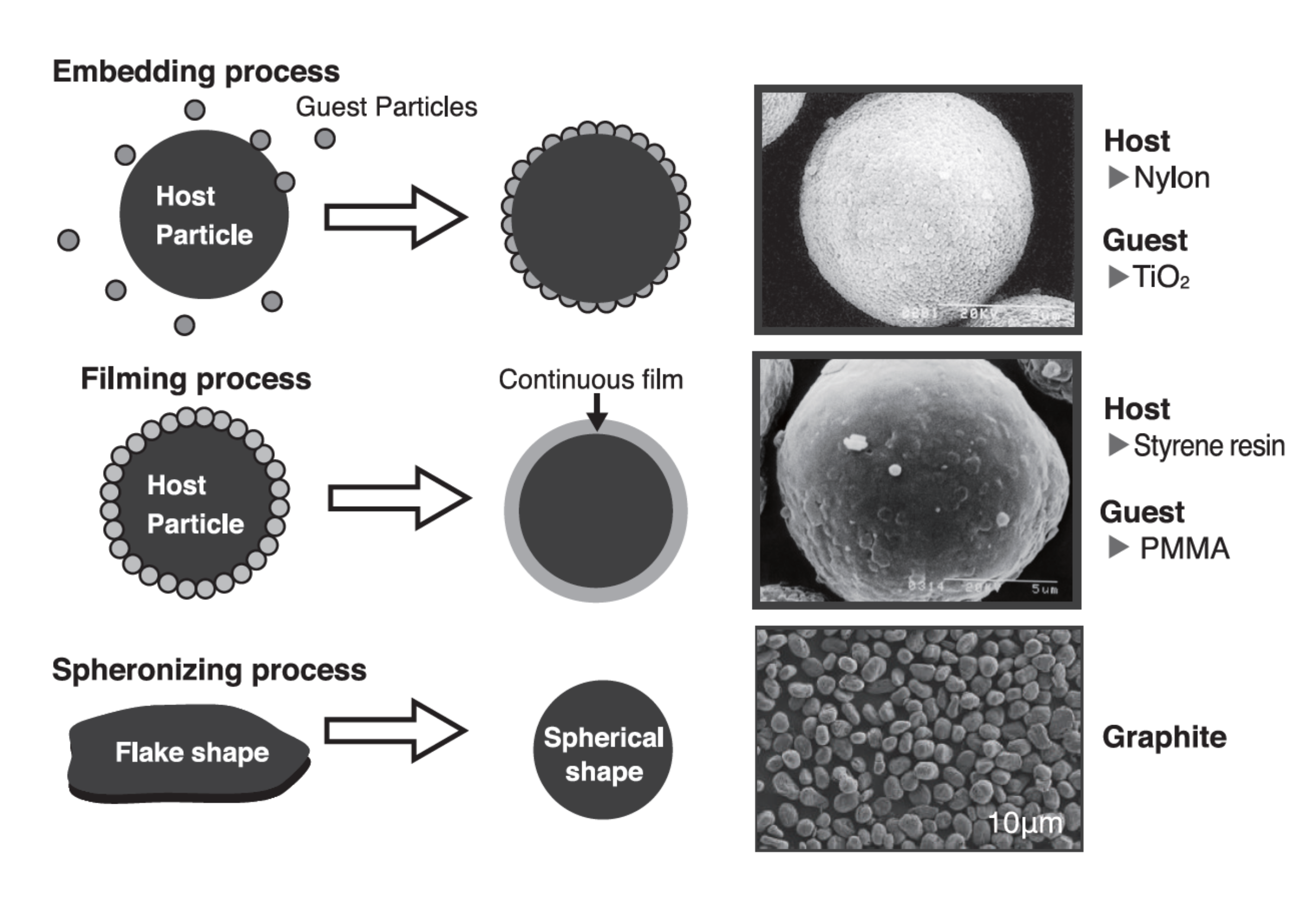

The surface modification can be achieved by the following different methods:

Spheronization (Rounding), embedding, penetrating and coating/filming (micro encapsulation). During hybridization process fine particles are applied onto or on the surface of a core particle.

By employing these methods of surface modification or formulation of powder composites, the NHS process has the ability to enhance conventional materials or even create new ones.

Types of Surface Modification

Embedding

Fine particles penetrate the surface of the core material.

Filming

Fine particles are plastically deformed – resulting in a complete coating of the core material.

Spheronization / Rounding

Raw material processing in the hybridization system achieves spheronized / rounded particles.

Advantages

- Improvement of dispersion, fluidization, wettability, electric or magnetic properties, catalytic properties, colour, weather resistance, light resistance, solubility, sintering properties, surface structure control, protection of reactions, controlled release, etc.

- High versatility since the combination of powder materials are infinite.

- Excellent dispersion of particles since the particles are processed in a high-speed air flow.

- Closed system with inert gas is possible to prevent oxidization of materials, for example metal fine particles.

- Solvent-free, dry powder coating process

Applications

- Battery materials

- Toner

- Luminescent materials

- Pharmaceuticals

- Food

- Paints

- Pigments

- Catalysts

- Cosmetics

- Electro ceramics

- Polishing materials

- Magnetic materials

- Biomaterials

- Optical materials

Application Examples – Spheronization of Anode Material

The NHS can achieve significant results in the spheronization of graphite as one of the commonly used anode materials improving both the bulk density and flowability.

Before and After Graphite Processing

Technical Data

| Type | NHS-0 | NHS-1 | NHS-2 | NHS-3 | NHS-4 | NHS-5 |

| Power [kW] | 2.2 | 11 | 22 | 45 | 90 | 185 |

| Powder amount [g/batch] | 50 | 400 | 800 | 1600 | 3200 | 6400 |

| Rotor diameter [mm] | 118 | 230 | 330 | 470 | 670 | 948 |

NHS-5 for Production

We are happy to manufacture according to your requirements.

Contact

Our team can support you with price information, product information and live demonstrations.

frankfurt@djkeurope.com

Phone: +49 6196 77614-11

Fax: +49 6196 77614-19