Charging and Discharging Inspection Equipment

SoftEnergy Controls Inc.

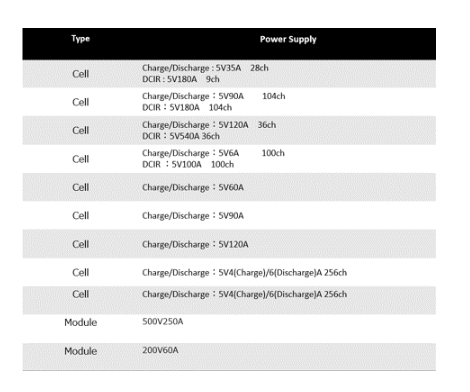

Charge and discharge equipment is one of the most important processes in lithium-ion battery manufacturing to determine the quality of lithium-ion batteries by repeatedly charging and discharging them at a specified current, voltage, and temperature. High-precision charge/discharge inspection, excellent safety, and energy saving are required at the same time. We manufacture advanced charge/discharge testing equipment based on our unique electrical control technology, and have sold many of these products to users in Japan and overseas. In addition to our existing power supply lineup, we develop power supplies to meet required specifications, and can handle everything from testing equipment to mass production machines.

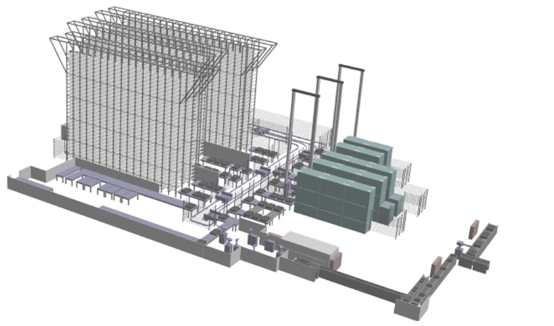

Mass production equipment

Not only charging and discharging unit, we offer fully automated formation line, including battery transportation system and aging system, as a turnkey solution provider.

Key Features

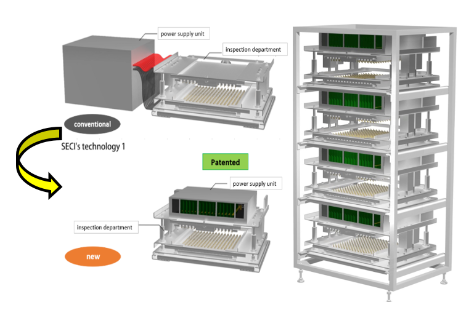

Compact & Cost

Space saving is realized by integrating the mechanical unit and power supply. Space saving leads to effective utilization of factory space and reduction of running costs for air conditioning, etc.

AC Regenerative Power Supply

Power can be returned to the building side during discharge (Regenerative efficiency is 70% (battery end to AC200V input end). We can make proposals from the viewpoint of clean energy and SDGs.

Cycler equipment

Battery performance can be evaluated by checking the deterioration of batteries after repeated charging and discharging. We also offer a constant-temperature chamber integrated type, which can be used under various conditions.

Battery Types

We handle all types of batteries -> Cell/module/pack, prismatic/cylindrical/laminate type, etc.

Delivery records

Contact

Our team can support you with price information, product information and live demonstrations.

frankfurt@djkeurope.com

Phone: +49 6196 77614-11

Fax: +49 6196 77614-19