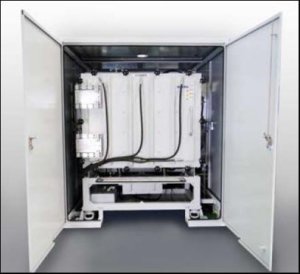

Vacuum Bake Purificationer

High temperature vacuum heating furnace with chlorine gas

Product overview

This equipment is chlorine gas compatible purification furnace that aims to remove and purify metal impurities in carbon and inorganic materials used for LiB and electronic components.

By using chlorine gas, it is possible to purify by dry method and remove metal impurities without damage to carbon and inorganic materials.

Model :

NBP-800 (CE Mark type)

Heating area W740×L740×H650 (mm)

Carbon purity up to 99,9%

Principle of Purification

By reacting impurities such as Fe, Co, and Mn with CL2 heated to a high temperature, it is purged to the outside of the furnace as chloride vapor.

At this time, impurities can be removed without damage to the material.

Types of purification methods

1.Wet cleaning by acid solution Waste liquid treatment is required After cleaning process, materials need to be rinsed, dried and crushed.

2.High temperature treatment (+ Vacuum) Requires ultra-high temperature → Damage to materials Difficult to process vaporized metal impurities → Exhaust system malfunction occurred

Chlorine gas Purification

Chloride metal impurities by chlorine gas (chlorine + vacuum)

Effect of chlorine

The processing temp. drops (processing of about 1000 ℃ is possible)

- No damage to material

- Reduced processing time

Effect of vacuum

Boiling point is lower than atmospheric pressure

- Promotion of vaporization process

- Increased contact probability between chlorine and metal impurities

Demo Furnace

We have a demo cleaner of NBP-470 type. Demo tests with various process gases (H2, Cl2, HCL, N2) are possible.

Contact

Our team can support you with price information, product information and live demonstrations.

frankfurt@djkeurope.com

Phone: +49 6196 77614-11

Fax: +49 6196 77614-19