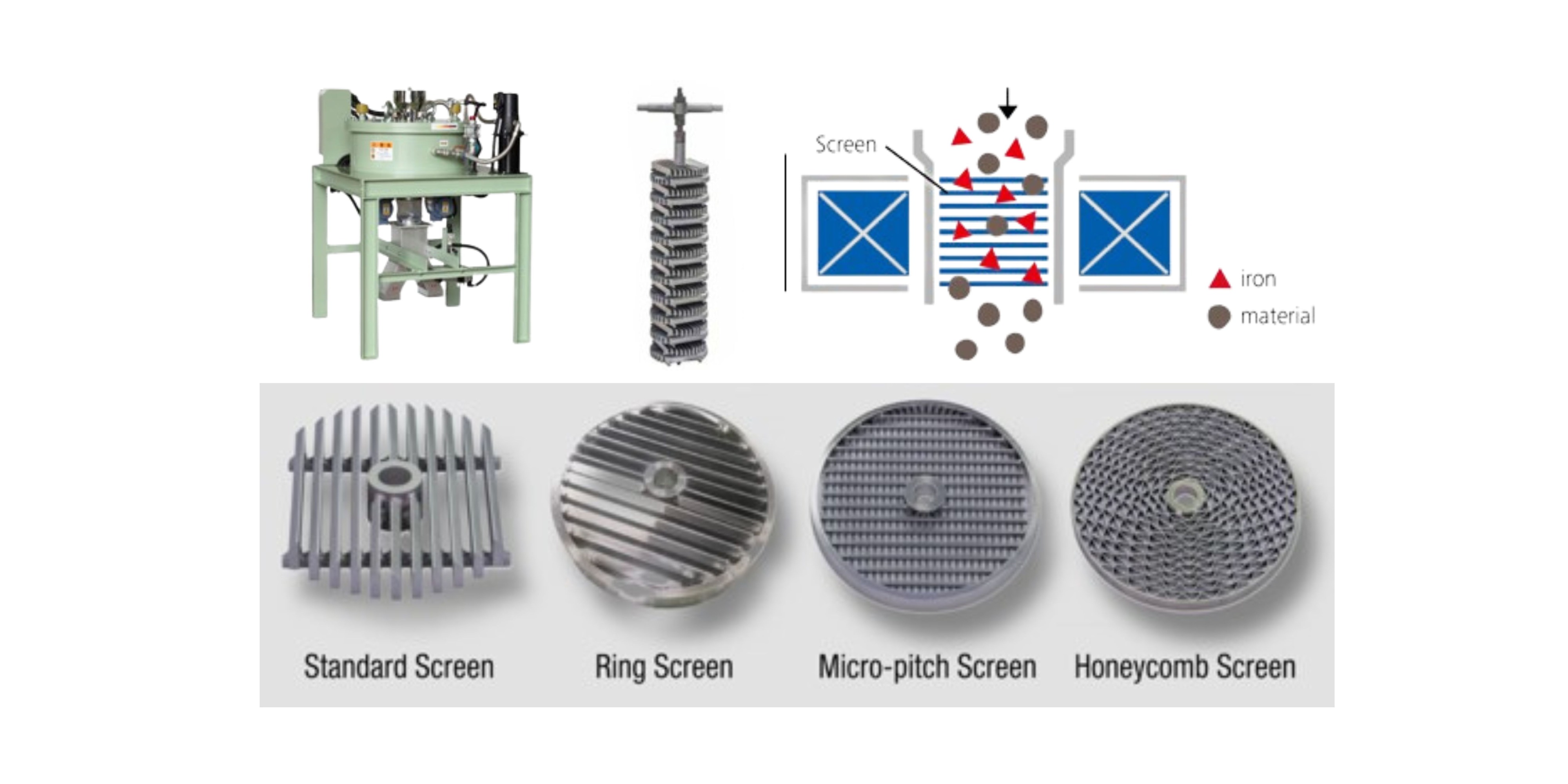

Electromagnetic Separator

Electromagnetic Separator (EMS) removes metal contamination from processs materials. Magnetic separation enables the effective removal of impurities and undesirable materials from battery materials, ensuring the production of high-quality cathode and anode materials. By selectively capturing and separating magnetic particles, this process helps improve the performance, consistency, and safety of battery materials.

Electromagnectic Features:

- From R&D scale to mass production scale

- Several types of magnetic screens available

- Magnetic force up to 19,000 GAUSS

Applications

Battery precursor materials

- Lithium-ion battery cathode active materials (CAM) Lithium cobalt oxide (LCO), Nickel cobalt manganese (NCM), Nickel cobalt aluminum (NCA), Lithium iron phosphate (LFP)

- Lithium-ion battery anode materials (AAM) Carbon, graphite, silicon anode, LTO

- Carbon additives

- Lithium carbonate

- Lithium hydroxide

- Slurry of active materials

Contact

Our team can support you with price information, product information and live demonstrations.

frankfurt@djkeurope.com

Phone: +49 6196 77614-11

Fax: +49 6196 77614-19