Roller Hearth Kiln Solutions for Battery Material Calcination

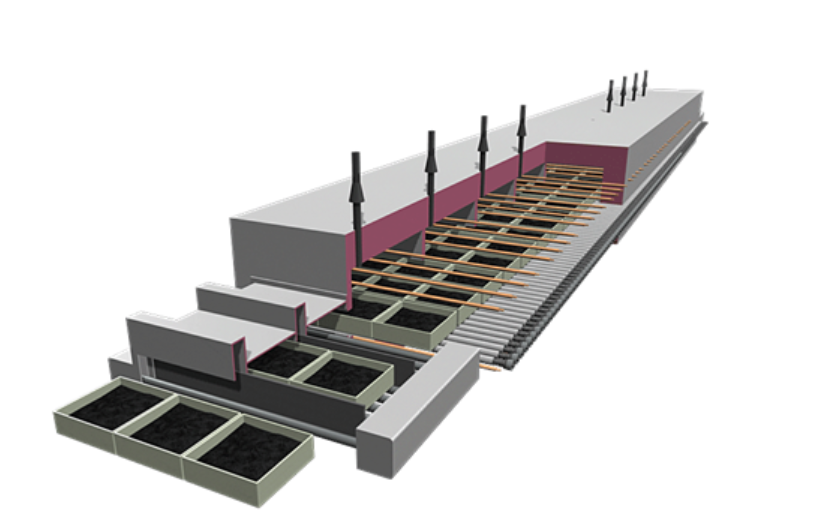

What is Roller Hearth Kiln (RHK)?

Roller Hearth Kiln (RHK) is a continuous firing furnace which transports products using ceramic rollers. RHK provides outstanding temperature uniformity, cleanliness and heat efficiency.

- Uniform Temperature Distribution: RHK’s roller transportation method makes radiant heating from all direction possible

- Clean Atmosphere: RHK materials are composed of ceramics which helps maintain a clean atmosphere

- Energy Saving and Space Saving: The combination of uniform heating and high speed firing allow for high efficiency production with energy and space savings

Roller Hearth Kiln (RHK):

We have experienced many projects globally for Lithium ion battery cathode and anode active materials:

- From R&D scale to pilot scale and mass production scale

- Uniform temperature distribution

- High throughput by utilizing special rollers

- Best insulation material selection to fit customers’ application

- Gas flow control

- High speed continuous firing

- Temperature : up to 1,620℃

- All ceramic materials used inside the firing chamber – No metal contamination

- Tailor made design for your materials and factory layout

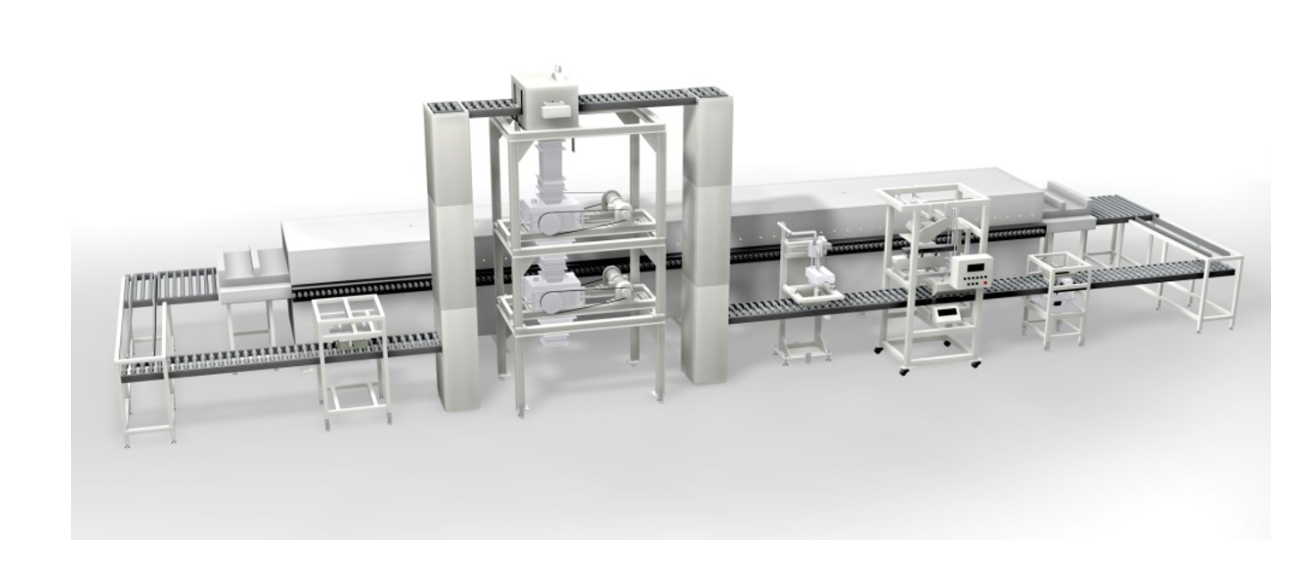

- Fully automated sagger handling system (option)

Roller Hearth Kiln is best solution for Lithium-ion battery materials

We can offer automated sagger handling systems for your production. The Lithium-ion battery market requires large amount of cathode and anode production. Our sagger handling system can cover high volume production rates with optimized footprints.

Our Experiences

- Lithium-ion battery cathode materials (All types of cathode active materials; LCO, NCM, NCA, LFP, etc)

- Lithium-ion battery anode materials (All types of anode materials; Carbon, Silicon Anode, LTO)

- Electrolyte materials for solid state battery

- Ceramic materials; Alumina, Zirconia and others

- Solid Oxide Fuel Cells

- MLCC

Contact

Our team can support you with price information, product information and live demonstrations.

frankfurt@djkeurope.com

Phone: +49 6196 77614-11

Fax: +49 6196 77614-19