Milling process in CAM/AAM production

Importance of Milling in Battery Material Production

In the production of battery cathode active materials (e.g., NCM, LFP) and anode materials (e.g., silicon anode), milling plays a pivotal role in achieving optimal electrochemical performance.

- Particle Size Control:

Milling allows precise control over particle sizes, ensuring uniformity and enhancing electrode performance. Smaller particle sizes translate to larger surface areas, facilitating faster ion diffusion and better electrochemical reactions. - Homogeneous Distribution:

Milling ensures even distribution of active materials, conductive additives, and binders. This homogeneity enhances electrode integrity, promotes efficient charge transfer, and reduces internal resistance. - Reactivity Enhancement:

Finely milled particles exhibit increased reactivity due to greater exposed surface area. This enhances charge and discharge rates, leading to improved battery power and performance.

Examples of Milling Equipment

We can propose all sorts of milling equipment depending on your material and requirement.

Below are just examples of equipment that we have experience on delivering it to our customers mainly producing cathode active materials and anode materials. Please feel free to contact us if you have any interest in milling processes.

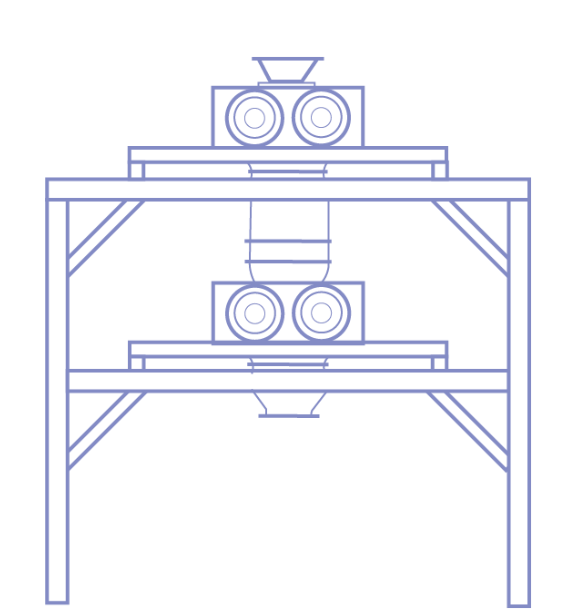

- Roll Mills:

Roll mills are versatile and commonly used for particle size reduction in battery material production. They consist of two rotating rollers that crush and grind materials, producing finely milled powders. Roll mills are suitable for a range of materials, including NCM and LFP cathode materials after calcination.

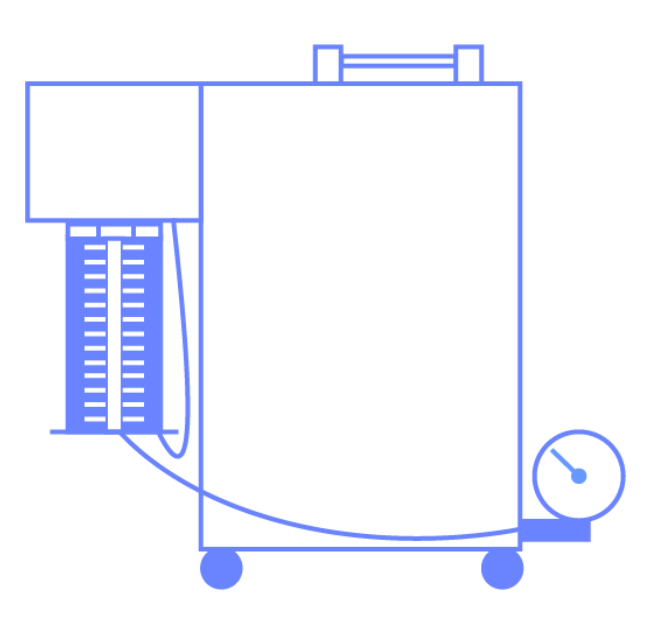

- Beads Mills (Wet Mill):

Also known as wet mills or bead milling equipment, beads mills are used in the production of battery materials, particularly in the processing of electrode materials.

Bead mills are capable of finely grinding and reducing the particle size of electrode materials, which is crucial for improving the performance of batteries. Smaller particle sizes provide a larger surface area, which can enhance the material’s electrochemical reactivity. These are commonly used for materials that are required to reach a particle size below 1 microns. For example, LFP and silicon anode materials, specifically speaking with battery materials.

- Jet Mills:

Jet mills utilize high-speed jets of air or gas to pulverize materials into fine particles. They are suitable for fragile or heat-sensitive materials like lithium hydroxide and lithium carbonate. Jet mills provide precise particle size control without the need for mechanical contact. - Classifier Mills:

Classifier mills combine milling and classification processes. They’re suitable for producing narrow particle size distributions. These mills are ideal for materials like silicon anode, where controlling particle size and distribution is crucial. Milling is a fundamental step in battery material production and lithium processing, influencing particle size, distribution, and reactivity. Employing specialized milling equipment like roll mills, jet mills, and classifier mills ensures the desired material characteristics are achieved for various battery cathode and anode materials, as well as lithium compounds.For high-quality milling equipment designed for battery material production, explore our range of roll mills, jet mills, and classifier mills to elevate your materials to the next level of performance and efficiency.

Milling is a fundamental step in battery material production and lithium processing, influencing particle size, distribution, and reactivity. Employing specialized milling equipment like roll mills, jet mills, and classifier mills ensures the desired material characteristics are achieved for various battery cathode and anode materials, as well as lithium compounds.

For high-quality milling equipment designed for battery material production, explore our range of roll mills, jet mills, and classifier mills to elevate your materials to the next level of performance and efficiency.

Contact

Our team can support you with price information, product information and live demonstrations.

frankfurt@djkeurope.com

Phone: +49 6196 77614-11

Fax: +49 6196 77614-19